WHATSAPP : +86 15959390943

EMAIL : Claire.ye@igreenequip.com

WHATSAPP : +86 15959390943

EMAIL : Claire.ye@igreenequip.com

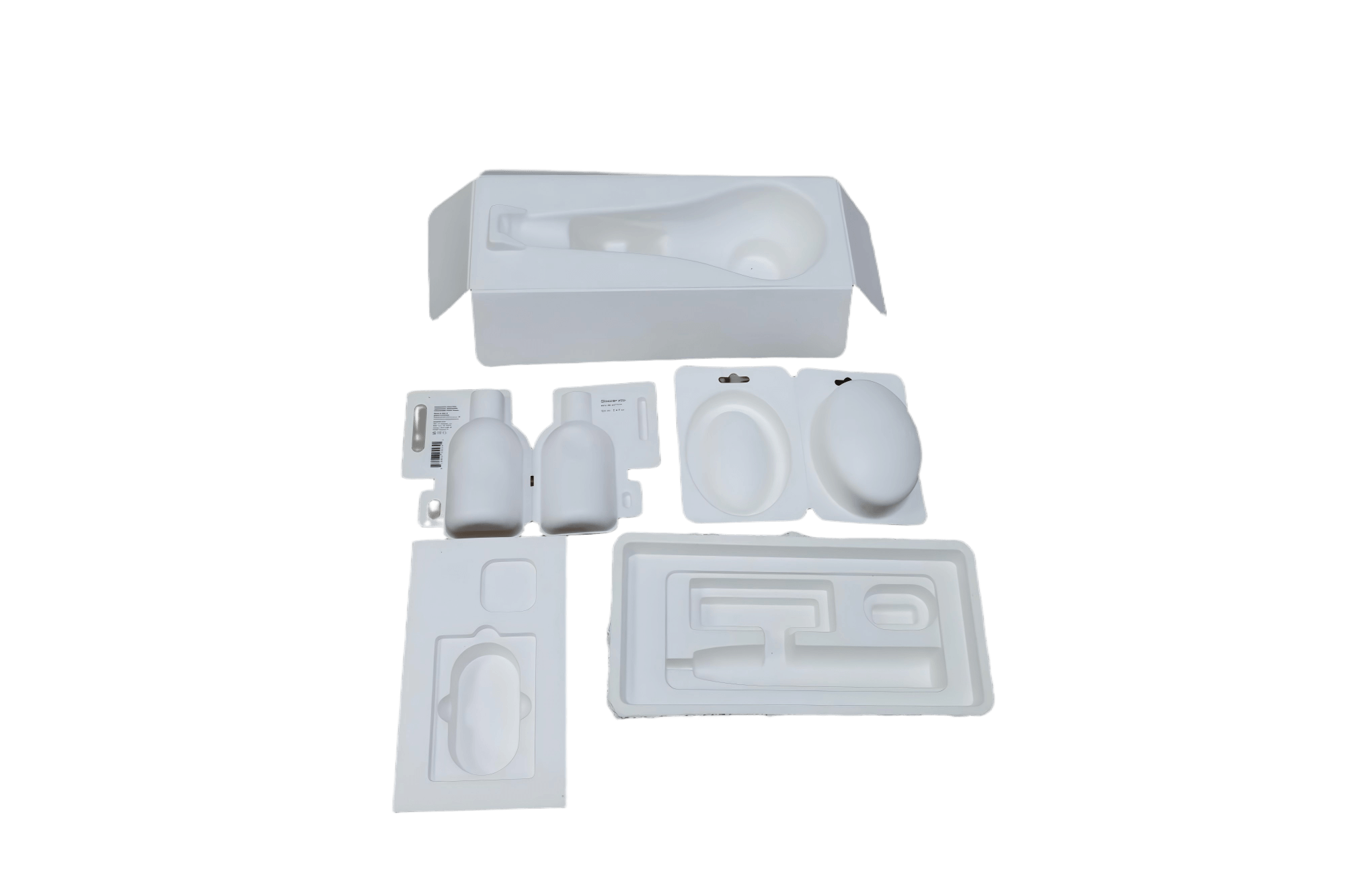

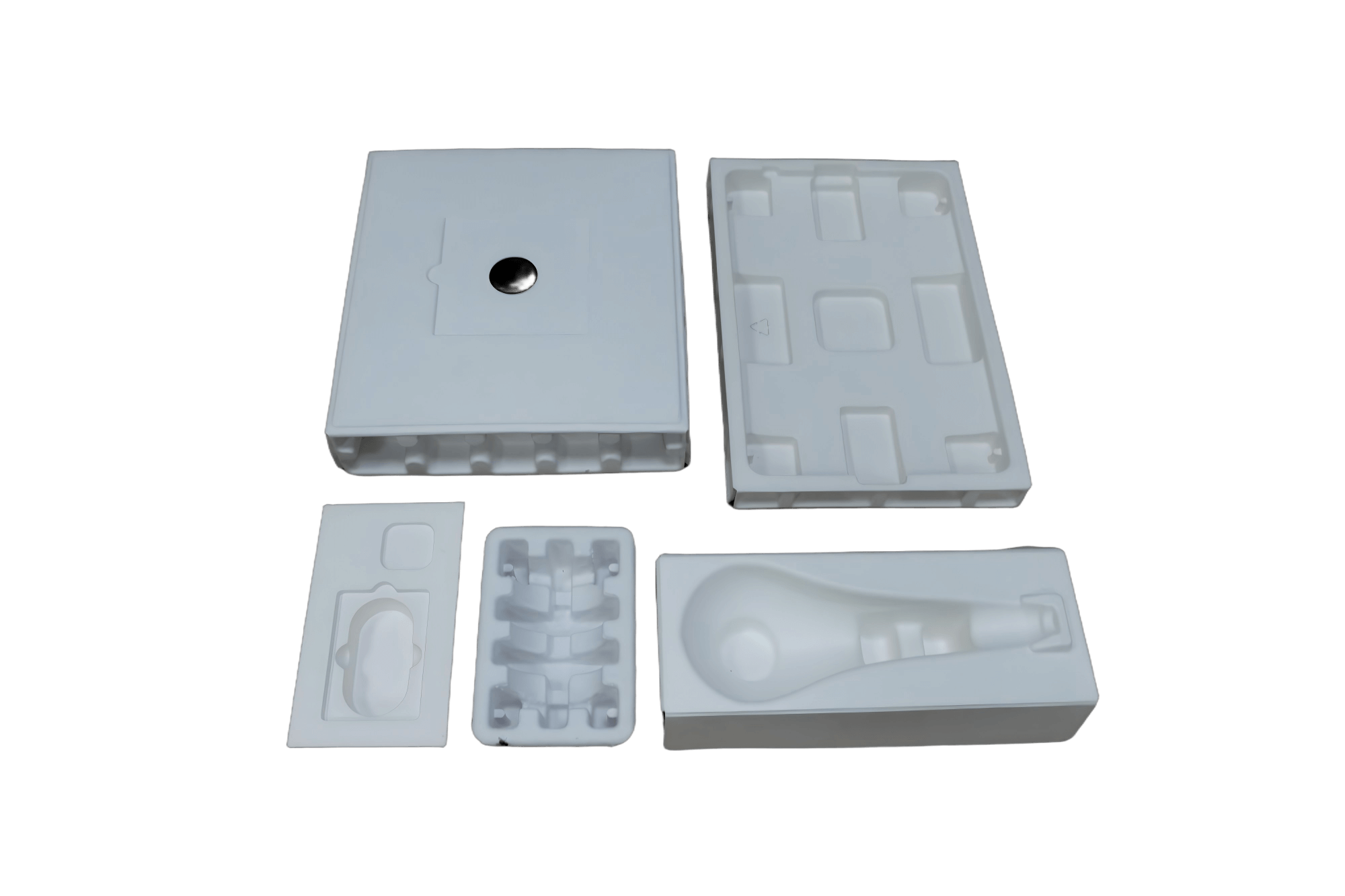

Pulp molded premium industrial packaging.--ECO-PACK & Biodegradable and compostable.

Environmental protection trend and are the first to replace their original plastic packaging with pulp molded premium industrial packaging.

The premium workpiece package is a more refined product made by using molds to shape the pulp through vacuum adsorption, drying, and further processing.

The pulp is made from one-year-old herbaceous plants such as sugarcane pulp and reed pulp, which are used to produce pulp boards.

Item No :

Pulp molding industrial PackageOrder(MOQ) :

10000PCSPayment :

TT &LCProduct Origin :

CHINAColor :

BROWN & WHITEShipping Port :

XIAMEN PORTLead Time :

20-30daysWeight :

Customer customizationAs countries around the world are announcing their carbon neutrality goals, leading brands from various fields are also adopting zero-plastic packaging. In the electronics industry, an increasing number of leading brands are using green packaging materials. For instance, for the packaging of products such as mobile phones, headphones, and electronic accessories, multinational giants like Huawei, Apple, and Samsung are following the green and environmental protection trend and are the first to replace their original plastic packaging with pulp molded premium industrial packaging.

The pulp is made from one-year-old herbaceous plants such as sugarcane pulp and reed pulp, which are used to produce pulp boards.

Pulp molded products, as an emerging environmentally friendly and green product, can be recycled and reused throughout their entire lifecycle, from raw materials, production processes to the disposal of waste. Currently, there are two main production methods for pulp molding: one is the wet pressing process; the other is the common traditional process (i.e., the dry pressing process). The raw materials used for producing disposable tableware and high-end industrial packaging products are generally sugarcane bagasse pulp, bamboo pulp, wheat straw pulp, straw pulp, reed pulp, etc.

The semi-automatic pulp molding machine is designed based on the principles of papermaking technology, vacuum filtration, and vacuum heat and mass transfer theory. Compared with other similar equipment at home and abroad, it has the following features and innovations.

Through the suction filtration forming rheological process of materials, the production raw materials are completely made of herbaceous plant fiber pulp, without the need for wood, effectively saving forest resources, protecting the ecological environment, and having low cost and wide sources.

The production process is advanced. The entire production process (from slurry injection to finished product packaging) is automatically completed on two machines. The production process is a closed-loop cycle without emissions and causes no pollution at all.

The production equipment is of an integrated and modular type, with a wide range of applications and strong versatility. By simply changing the molds, different products can be produced. It can be connected in any combination to form production lines of different scales, and a single production line can simultaneously produce various types of high-quality work packages.

Tags :

Related Products

Hi! Click one of our members below to chat on