WHATSAPP : +86 15959390943

EMAIL : Claire.ye@igreenequip.com

WHATSAPP : +86 15959390943

EMAIL : Claire.ye@igreenequip.com

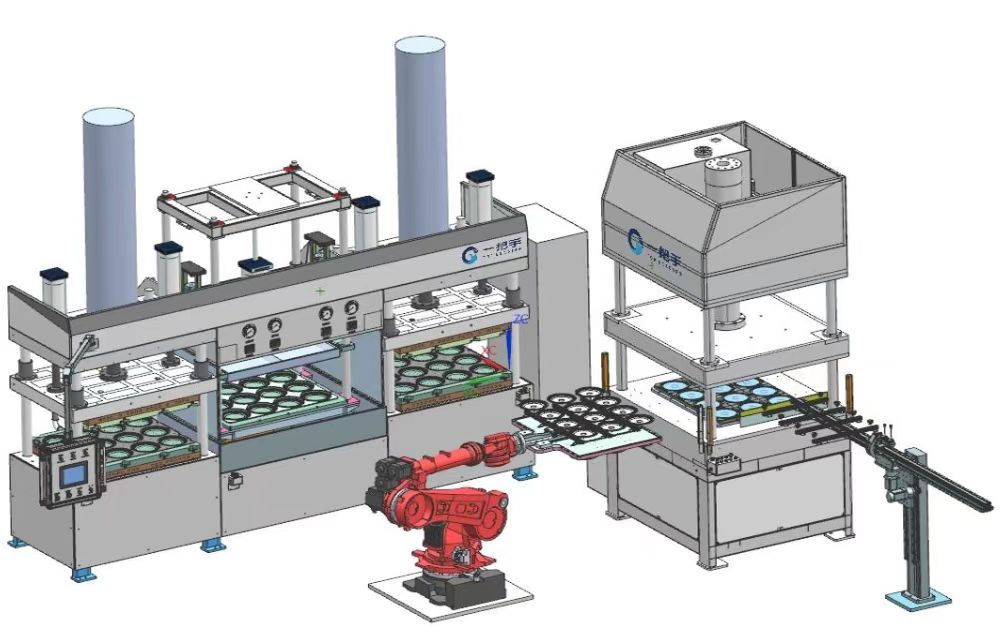

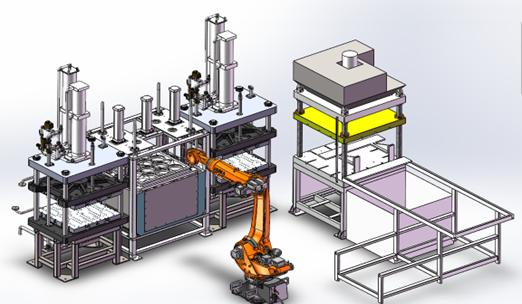

Biodegradable and compostable fiber pulp molding food packaging tableware thermoforming machine+robort

Paper pulp molded tablware machine -Semi-automatic machine &with robort

Our machine guarantees a 50% energy saving, a finished product rate of over 95%, and a service life of more than 15 years for both the machine and mold.

We offers both energy-saving semi-automatic machines and energy-saving free trimming, free punching automatic machines in this category. we provide the option oil heating and electric heating for customers.

Item No :

GYC-2022-RobortOrder(MOQ) :

2SETPayment :

CONTACTProduct Origin :

CHINAColor :

CUSTOMERMIZEDShipping Port :

CHINA PORTLead Time :

50-60 DAYSWeight :

7TONHighly advanced technologies are applied in the designing, manufacturing, and testing of Disposable Biodegradable Pulp Molding Tableware Production Line Sugarcane Bagasse Paper Plate Making Machine.With the proven quality and multifunctional features, it can be found in the field(s) of Paper Product Making Machinery.

The pursuit of efficiency and precision in pulp molded tableware manufacturing has led to a divergence in technological approaches: semi-automatic machines and robotic systems. Understanding the nuances of each is crucial for businesses seeking optimal production solu

Due to the devotion of our employees such as designers and R&D experts, it is designed to be eye-catching in its appearance and powerful in its newly-updated functions. With it's excellent features.

Streamlined Production

The good edge trimming, punching capabilities, along with automatic collection and intelligent counting features, revolutionize the production process. With total trimming and punching, there is no need for additional, time - consuming and resource - intensive secondary operations. This simplifies the manufacturing workflow, reducing the risk of errors that can occur during multiple processing steps.

Robotic systems, on the other hand, offer a higher degree of automation. Robots handle product transfer, trimming, and stacking with speed and precision, minimizing human intervention and maximizing throughput. This results in consistent product quality, reduced labor costs, and a safer working environment. However, the initial investment is significantly higher, and the system may require specialized programming and maintenance. Furthermore, robotic systems can be less adaptable to frequent product changes or complex designs, potentially limiting their versatility.

The choice between semi-automatic and robotic systems hinges on a careful evaluation of production volume, product complexity, budget constraints, and the availability of skilled labor. Semi-automatic machines are well-suited for smaller-scale operations with diverse product lines, while robotic systems offer a compelling solution for high-volume production of standardized tableware. Ultimately, the optimal path lies in aligning the level of automation with the specific needs and resources of the manufacturer.

| Product Parameter | |

| Automatic | Semi--automatic with Robort |

| Designed Capacity | 450-550kg/day |

| forming type | vacuum suction |

| Mould Material | Aluminium Alloy:6061 |

| Raw material | plant fiber pulp (any paper pulp) |

| Drying method | heating in mold(by eleatric or by oil ) |

| Auxiliary Equipment Power For Each Machine | 25.5KW For Each Machine |

| Vacuum Requirement For Each Machine | 9m3/min/set |

| Air Requirement For Each Machine | 1.3m3/min/set |

| After-sales Service | Free spare parts, Video technical support, installation guidance, commssioning |

| Place of Origin | Xiamen city ,China |

| Finished Products | Disposable ECO-friendly Tableware |

| Accepted Payment Type | L/C ,T/T |

| Accepted Payment Currency | CNY,USD |

| Applicable Industries | Manufacturing Plant | Showroom Location | None |

| Condition | New | Product Type | Paper tableware machine |

| Processing Type | Pulp Molding Machine WITH ROBORT | Place of Origin | Fujian, China |

| Brand Name | GYC-DS | Voltage | contact us |

| Power | contact us | Dimension(L*W*H) | contact us |

| Weight | 1700 kg | Warranty | 1 Year |

| Production Capacity | about 700-800kgs,(working hour≥23H/day) | Machinery Test Report | Provided |

| Video outgoing-inspection | Provided | Marketing Type | New Product 2022 |

| Warranty of core components | 1.5 years | Core Components | PLC, Engine, Motor |

| Product Name | GYC-P09 Biodegradable Disposable Sugarcane Bagasse Pulp Machine | After-sales Service Provided | Field installation, commissioning and training/Online support |

Industry Pioneer

Industry Pioneer

Tags :

Related Products

Hi! Click one of our members below to chat on